Hygrade Casting will be closed from 20th December 2024 and re-opening again 20th January 2025. Merry Christmas & Happy New Year!

Hygrade Casting will be closed from 20th December 2024 and re-opening again 20th January 2025. Merry Christmas & Happy New Year!

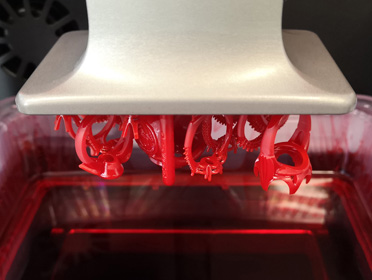

Our 3D printing arsenal features the latest SLA (stereolithography) printers from the United States and Asia, calibrated to a precise 45-micron layer thickness. This ensures an industry acceptable finish on castable resins, reducing the time you spend on cleaning and polishing.

We exclusively use premium OEM-approved resins and employ multiple pure solvent baths to clean each printed resin thoroughly. After cleaning, we go the extra mile by using a dedicated airbrush with 100% pure clean solvent to ensure every resin is spotless before casting. While this process involves more time, consumables, and wear on our equipment, the result is a cleaner, smoother casting for you.

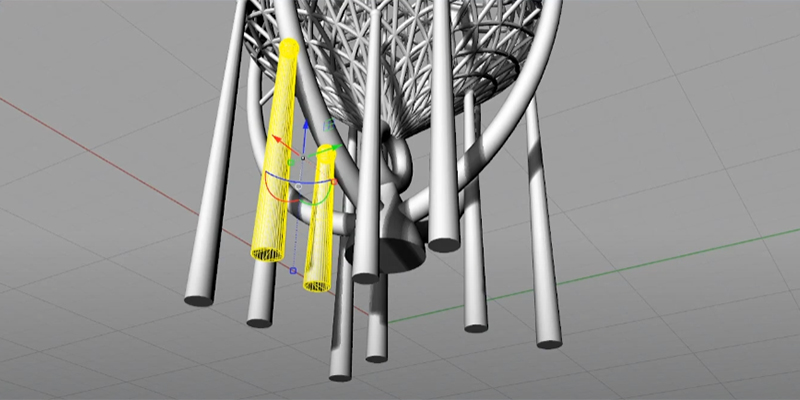

You must have the sprue already included in your CAD designs or STL files. We don’t add sprues ourselves to avoid misunderstandings, as some business owners may be sceptical, suspecting excess sprue design to increase chargeable metal weight. To avoid such concerns, we ask that your CAD designer incorporate the sprue into your design, which should only take an additional one-two minutes.

We will soon provide sample images of acceptable sprue designs.

Below are the timeframes and pricing for 3D printing services. Please note, these timeframes only apply to 3D printing and do not include casting times, to see our casting time table please visit our casting tab above.

From: $55.00 + GST per item

We do not offer CAD/STL drawing services

From: $175.00 + GST per item

We do not offer CAD/STL drawing services

The terms and conditions below are non-negotiable. The words "we" and "our" refer to Hygrade Casting.