Hygrade Casting will be closed from 20th December 2024 and re-opening again 20th January 2025. Merry Christmas & Happy New Year!

Hygrade Casting will be closed from 20th December 2024 and re-opening again 20th January 2025. Merry Christmas & Happy New Year!

Tired of dealing with outdated casting houses stuck in their ‘old-school ways’? We're here to change that. Our young, sharp, and fast team takes a logical, diligent approach to casting—leaving the boomer mindset behind.

We’ve trained under some of the best precious metal casting technicians from Australia, Germany, and Turkey. But we didn’t stop there—we've refined those methods to offer ultra-clean, dense precious metal castings.

We work with high-end business owners (jewellery retail shops and workshops), dental clinics, and even individual members of the public who need castings without all the hoops.

We use the crème de la crème of casting machinery from Germany,

with no expense spared.

Using medical-grade Argon and casting under vacuum, we eliminate gas porosity, resulting in cleaner, denser castings with superior colour and tensile strength.

(Psst—our in-house chemists make the master alloys themselves.)

At Hygrade Casting, quality is everything. We use the finest investment powders and distilled water, mixing them under a vacuum to banish bubbles.

Our unique 14-hour furnace burnout cycle ensures waxes and resins are fully burned out, leaving no ash behind.

The result? Consistent, reliable castings.

Perfected flask temperatures, casting pressures, and quenching times mean that miscasting, porosity, scorching, and brittleness are almost unheard of here. You’ll receive castings that are exceptionally clean, strong, and precise—with colours we believe are industry-leading.

Our standard finish is an abrasive-free "raw casting" finish, cleaned with high-pressure water and a hot acid bath. If you need shiny castings or hardening/annealing treatments, check out our post-processing services.

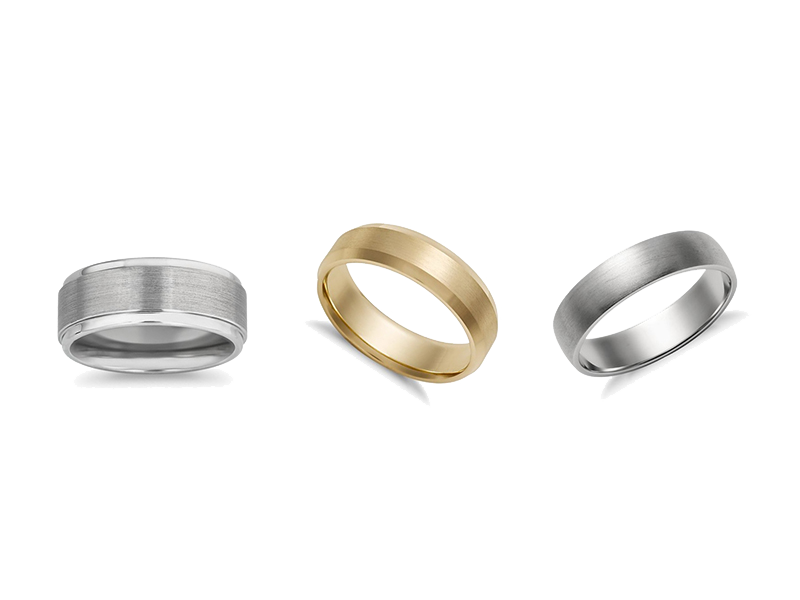

We’re picky about the metals we cast—and the clients we work with. Our high-end clientele values quality and precision over price and speed, so we focus on a select range of premium metals to ensure the best quality castings.

All of our castings are hypoallergenic, meaning they’re safe for wear (rings, earrings, pendants, etc.) as we refuse to use base metals like nickel.

Weekly

Weekly

Twice a Month

Twice a Month Once a Month

Once a MonthFor platinum and 24 Karat gold, casting is on the last Wednesday of each month. Resins/waxes must be in our hands by the last Tuesday of the month, no later than 11 a.m.

Platinum casting comes with significant fees due to the time, materials, and energy involved. It also has a high miscast rate because of how it behaves when superheated above 2,000°C. Even with that challenge, we maintain an 8/10 success rate with platinum.

At Hygrade Casting, transparency isn’t just a buzzword—it’s our mantra. We know many jewellers have been misled by "cheap" casting fees, but here’s why they’re too good to be true.

We don’t disguise our fees by offsetting them with inflated metal prices or watered-down metals (like paying for 18 Karat and getting 17.5 Karat). Many people don’t own a precious metal XRF scanner to verify the purity they’re paying for—but soon, we’ll provide an XRF scan with every casting to ensure you’re getting exactly what you paid for.

If you are a business that needs volume and regular castings (ie 25+ items a week), please contact us via email or phone as our rates are negotiable in these instances.

| 9 Karat & 18 Karat Yellow/White/Rose Gold & 925 Sterling Silver | |

| Small Earrings/Pendants | $20 + GST |

| Medium Rings/Earrings/Pendants | $35 + GST |

| Large Rings/Earrings/Pendants/Bangles | $50 + GST |

| 24 Karat Gold | $75 + GST |

| Platinum | $250 + GST |

After casting, cleaning, acid-bathing, and cutting your item, we weigh it using an NMI trade-approved scale. Our scale measures to three decimal points, ensuring accuracy (e.g., 4.132 grams is billed as 4.13 grams, and 4.135 grams as 4.14 grams).

If you opt for additional post-processing (like ultra-high shine), we reweigh the item post-processing to ensure accurate metal charges.

Precious metal prices fluctuate daily, and we’ll soon incorporate a pricing chart to reflect current rates.

Some metals just don’t make sense for us to cast. Here’s what we skip:

We also don’t cast non-precious metals like brass, bronze, copper, titanium, tungsten, aluminum, or any type of steel.